XPS, EPS, and PIR: a comparison in video

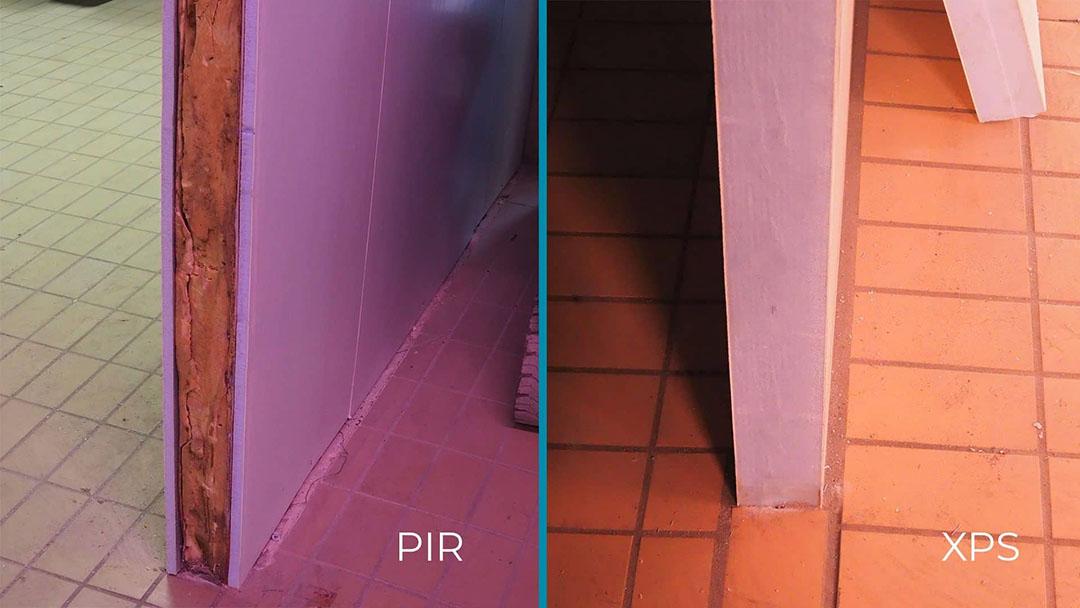

Insulated sandwich panels in XPS (extruded polystyrene) provide a guarantee of durability (return on investment) when used in the food industry.

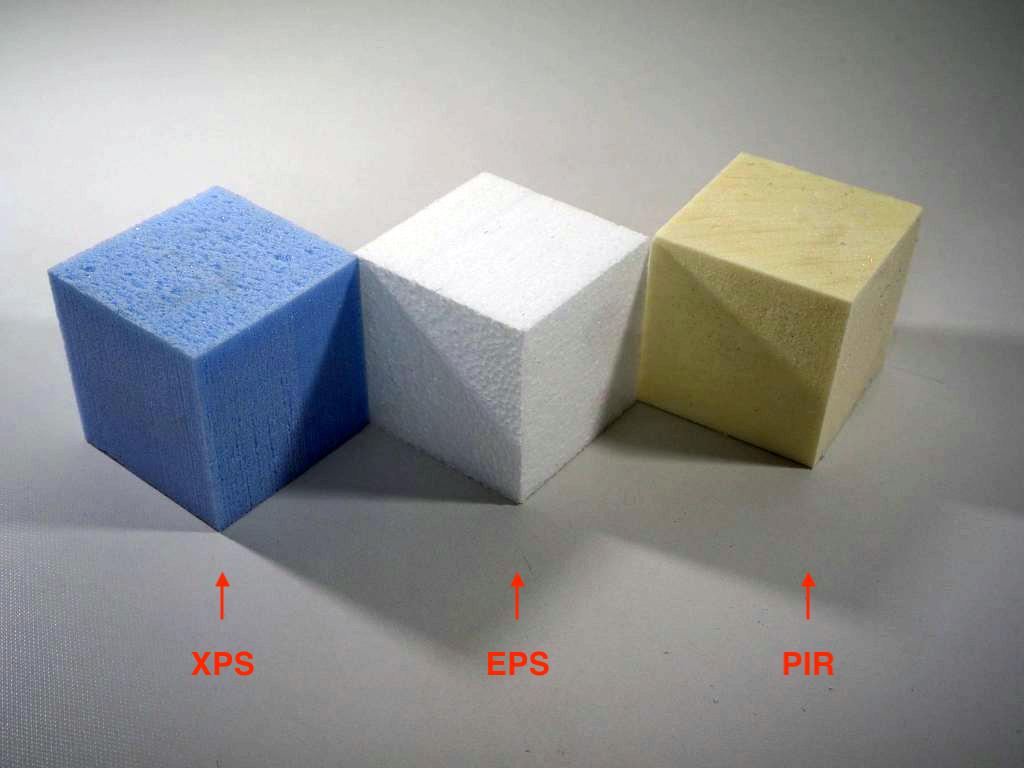

Differences between XPS (extruded polystyrene), EPS (expanded polystyrene), and PIR (polyisocyanurate) compared as cores of insulated sandwich panels.

What are the differences between extruded polystyrene XPS, expanded polystyrene EPS, or PIR?

A comparison in 4 different videos on which insulation material is most balanced for insulation.

The best insulation is the one that insulates best under the conditions in which it is used.

The choice depends on the application required, not personal preferences.

Each application will subject the material to different wear factors.

Therefore, to answer the question: 'Which insulation material is the most balanced?' it is necessary to examine several factors.

What is reported on the certificates almost never corresponds to the real working condition in which the insulation is found in food environments.

An insulation, in fact, does not maintain its initial characteristics forever.

It may, for example, be in a humid, wet environment, with joints between the panels more or less sealed in the presence of vapor in the air, subjected to external impacts, to intensive washings.